Custom Case Foam

Protecting fragile and vital equipment can often be accomplished using custom-cut foam fitted to your equipment. The correct foam must support the mass load and still cushion sensitive equipment from impact forces. There are numerous foam properties that influence foam selection from anti-bacterial foam, which is helpful for preventing mold growth in humid environments, to anti-static foam which protects delicate electronics.

Pelican Products, Inc is proud to have pioneered many processes for the correct use of foam in technical packaging. More than 40 years ago we developed the original “Fragility Curve” table, still in use around the world today.

Not all foam is created equal. To see all foam properties:

Fabricating Custom Foam Parts

Pelican’s Advanced Case Solution Centersare equipped with state of the art equipment for reliable, uniform foam parts. Computer controlled high speed water jet cutters rapidly produce precision “gang run” parts from foam sheets up to 8 feet wide. Pelican technicians use a variety of adhesives and raw materials to assemble layered foam parts into a single unit for the ultimate in equipment protection. From 25 foot long helicopter blades to micro-surgery instruments, we’ve seen it all.

CNC Case Foam Routing

Custom Foam Die Cutting

Design Your Own Foam

Have a simple project that you want design yourself? You can also design custom foam for several of our Pelican™ Protector Case™ and Storm Case™ models at:

foam.pelican.com

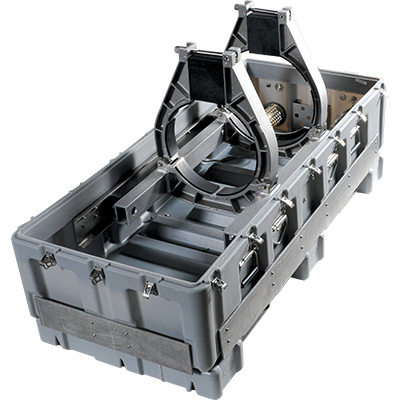

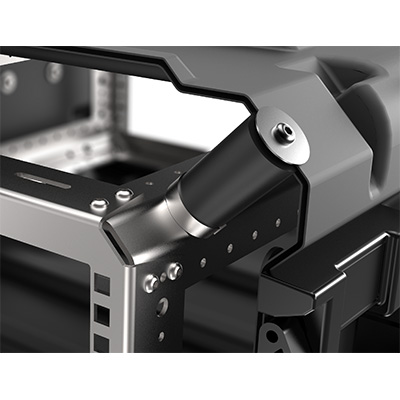

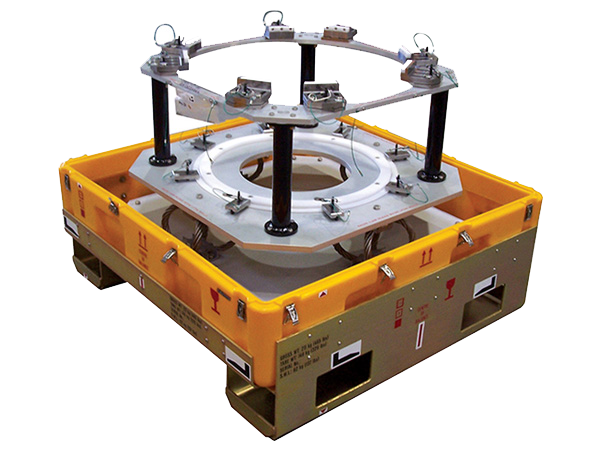

Cradle Suspension Systems

Shock from drops and vibration can be detrimental to electronics and sensitive equipment. Our cradle suspension systems are custom designed to mitigate these harmful forces. Pelican engineers can design custom solutions to protect equipment from shock and impact down to 15Gs.

Heavy or extremely fragile equipment sometimes requires fabrication of custom deck mount suspension systems. Pelican’s machine shop is world-class, with punch press, metal CNC, certified welders and finishing services demanded by the aerospace, defense and medical industries.

Watch the Cradle Suspension Systems video

Welded Cradle Mount

Wire Rope Isolator Cradle Mount

Shock Mount Isolators

Custom Logo and Colors

Personalize the outside of your case to match your company's branding. Add your company logo with our hot stamp imprint process, which is scratch resistant; or add a custom logo decal or engraved name plate.

Engraved name plate

Custom Logo Decal

Vibrant Hot Stamp Imprint

Optional Colors (for Single Lid and Rack Mount cases)

fed std # 26270

fed std # 20372

pantone # 292U

fed std # 27925

pantone # 012U

fed std # 24052

fed std # 12197

fed std # 23538

pantone # 202U

fed std # 25052

fed std # 27040

pantone # 245U

fed std # 34096

fed std # 21105

Standard Case Accessories

available for most Single-Lid, Deck-Lid and Rack Mount.

Casters

Edge Casters (standard on MAC with 5” lid)

Caster Storage in Lid

Metal or Comfort Grip Handles

Extra Handles

Card Holder

ID Plate

Front Labels

Standard Labels

Custom Stenciling

Airtight/Watertight

Coupling Catches

Humidity Indicator

Lid Hangers

Lid Storage Pouch

Lift Rings/ Tie Down Rings

Leg Kit Chair or Table

Lockable Cable Catch (1 set of 4 ea)